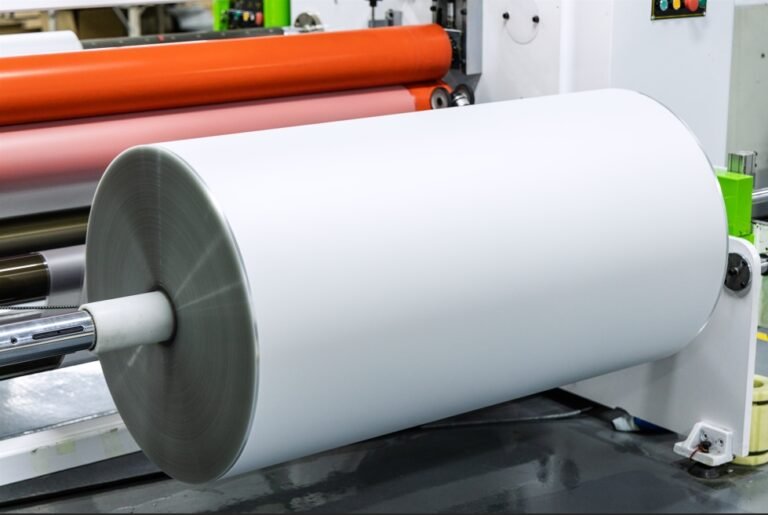

3D Sublimation Transfer Film

3D sublimation film is a specialized transfer film used to imprint high-resolution, durable designs onto three-dimensional objects. It consists of a base film (e.g., PET) coated with sublimation dyes that turn from solid to gas when heated. This gas bonds with polymer-coated surfaces (e.g., plastic, ceramics), creating a permanent, seamless design that wraps around curved or irregular shape

Main Features

Advansub Films

Specification in Details

| Color | Transparent/White |

| Default Thickness | 215+5um |

| Quantity | A3(25 sheet/bag), A4(50 sheets/bag), A5(100 sheets/bag), 240*148MM(50 sheets/bag), 243*149MM(50 sheets/bag), 260*170MM (50 sheets/bag), roll film specification 0.21*40M, 0.34*40M, 0.42*40M, 0.6*40M |

| Temperature | 130-200°C |

| Transfer Rate | Over 98% |

| Drying Time | Quick-drying |

| Elongation | 300% |

| Expiration Date | 12 Months |

Consumer Electronics

Phone/tablet cases, laptop covers, keycaps.

Sports & Lifestyle Products

Shin guards, bicycle helmets, Controllers, headsets with ergonomic designs

Automotive

Key fobs, interior trim components, door handles, and center consoles.

Industrial & Emerging Uses

Controllers, headsets with ergonomic designs

How to Use 3D Sublimation Transfer Film

Why Choose Advansub® Film

Our 3D sublimation transfer films are trusted worldwide, backed by rigorous quality control, dedicated customer support, and our factory’s proven manufacturing expertise

FAQs On Advansub Film

At present, films are used to printing mobile phone cases, computer cases, key caps, shinguards and other curved-surface products. In addition, we can also help customers with customized packages, such as smart door lock shell, car key shell, helmet, mobile phone accessories and so on.

Our company has a quality commitment warranty backed up with traceability code. If the quality is confirmed to be faulty, our company will unconditionally resend it to the customer with perfect one.

Definitely, our company can provide a complete set of technical assistances, such as printer settings, color adjustment, machine settings, problems that cuased by overstreched films and so on.

Regular sizes are A3, A4, A5, 240*148MM, 0.42*40M,0.43*40M,0.6*40M

Yes, then the MOQ is 1000 sheets of per size.

Yes, that at least you need to order 1000 bags.

Films must be used within one week if they are exposed to the air and the humidity is higher than 60%, , and the bag must be sealed after every single time you take films out from it, otherwise films are unavailable to use anymore once they got moisture.

Printed on the matte side, and after printing, place it in an oven at 55 degrees Celsius for roasting 20 minutes. If the pattern is particularly dark, you also need to blow it with a hair dryer for about 10 seconds before printing, which is in a bid to assure the high quality and optimize the efficiency of finished product.

This is because the film is not completely dry, so it cannot be sublimated. Every sheet of films need to be completely dry before sublimation job, otherwise bumpy spots/white fleck will be generated and some areas cannot be printed.

The workshop must be the enclosed one , especially in the rainy season, the window must not be opened, otherwise the printed pattern is easy to be diffusive (which means that the film has been wet). The humidity of the workshop should be controlled below 60 degrees to ensure the normal use of the film.

The implication of humidity greater than 60 degrees on film will be:

---The film will be prone to be culred up after printing

---Got moistured and faulty, unavailable anymore, only have to discard

---Become worthless due to the uneven/irregular patterns attached on the film

Yes, Advansub can provide free samples. Please contact us for a more detailed sample policy. To ensure you’re satisfied with the performance and quality, we’ll provide a graphic printing demo or physical consumables sample for your review.

Yes, as a manufacturer, Advansub offers customization services to meet your specific needs. You can customize the product's appearance, add your logo, or request tailored packaging designs. We also provide comprehensive OEM services. For more details, please share your ideas or inquiries by emailing us—we'd be happy to assist you!

Expert Support For Your Complete Satisfaction

The Advansub team is happy to support you with extensive knowledge in the field of Sublimation Film